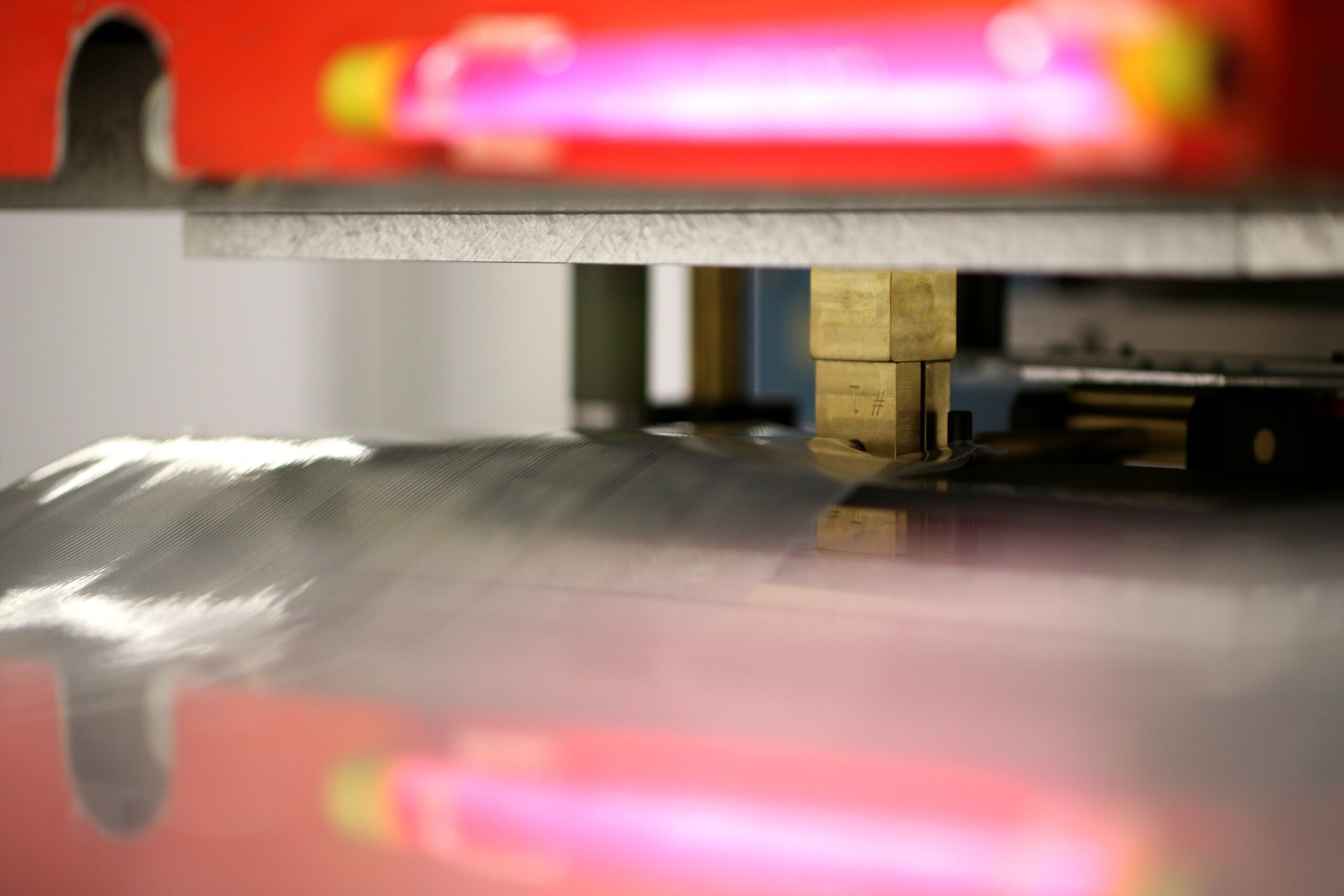

Radio Frequency & Ultrasonic Welding of Single-Use Devices

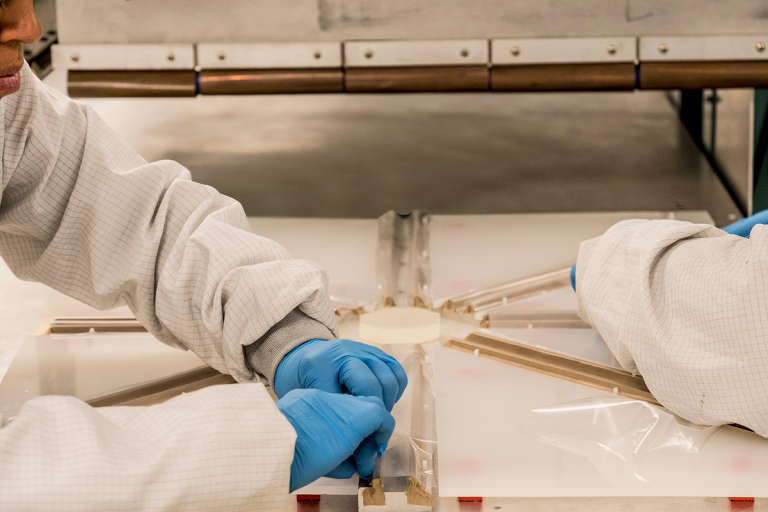

As OEMs help their healthcare and life sciences clients improve manufacturing of single-use products, you might find yourself scrambling to replace traditional materials with eco-friendly alternatives while ensuring your medical device remains profitable and effective. Just as challenging, many manufacturers are unable to achieve successful welds of certain materials for patient use. Let’s discuss the advantages of RF welding medical devices.

When you partner with Vonco, our proprietary Radio Frequency (RF) Welding of plastic products means your device will be far superior in its quality, durability and sustainability. Just as important, you’ll find a more efficient manufacturing process for custom medical device products and expanded design options, thus producing a better product. If you can draw it, we can weld it.

In all, RF welding benefits are plenty:

- More efficient processing.

- Improved quality.

- Eco-friendly alternative to toxic solvents and materials.

- Potential reduction of raw materials.

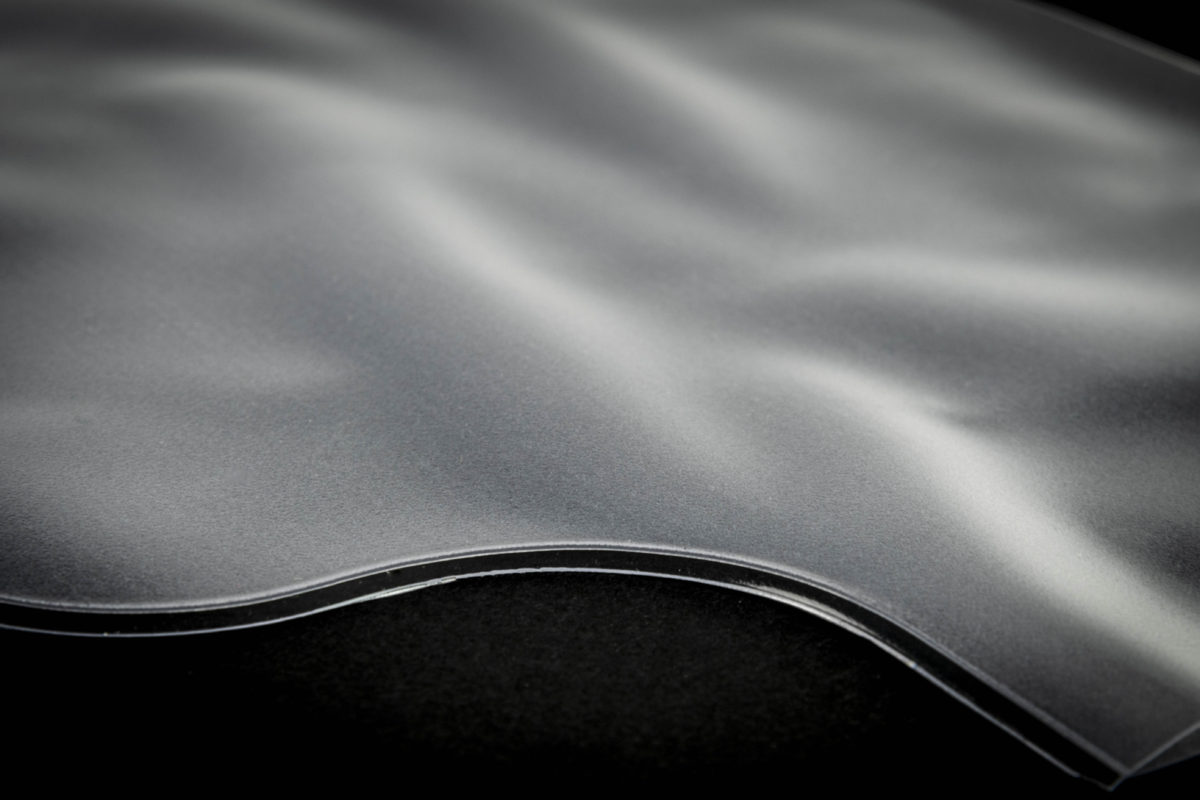

- Tighter, permanent bond as strong as the original material, translating into greater resilience.

- Greater process control with more complete, leak-proof welds.

- Safer option for patients with skin sensitivities to conventional materials (PVC, latex).

Common Alternatives to RF Welding

How does RF welding compare to conventional options?

Sewing: When stressed, threads can break under pressure, putting patients at considerable risk.

Gluing: Adhesives use hazardous solvents, harmful to the environment. They also wear out, and seams can eventually fail. Gluing also takes much longer than RF welding.

Hot Air: This method applies heat to the outside of the material to melt it and create a bond. This will not work for materials that are too thick, as the outside layers overheat and burn while the middle struggles to melt.

RF WELDING:

- When stressed, RF welds distribute that stress evenly through the material, enabling a stronger seam.

- Heats materials from the inside out, forming consistent, airtight seams.

- Best at withstanding pressure and preventing air, moisture or debris from getting in.

- Safe, compliant alternative to PVC, thermoplastic polyutherane (TPU), or natural rubber latex.

Sonic works better with rigid components

Common Devices

Medical devices your peers have entrusted to Vonco's RF welding include medical fluid delivery, storage and drainage bags, among others.

Quick Quote

Use this quick form to request more information from one of our experienced product experts.

Already know what you need? Click here

"*" indicates required fields